Characteristics

TGX10-25B inspects the contents of beverage bottles and cans. It captures and processes an x-ray image of the fill level to determine if the level is within the tolerances. High-speed and precision inspections are performed automatically in-line.

This inspection system is manufactured by Takashima Giken Co., Ltd.

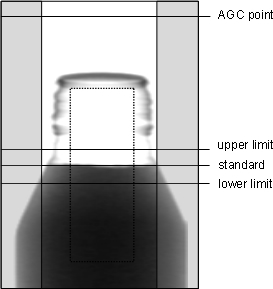

Sample image

The fill level can be correctly derermined by using X-rays even in steel or aluminum cans. Detection is not influenced by color differences, bubbling of the fluid, the label or other factors.

Specifications

| Inspection applications | 160 mL - 2.0 L PET bottles, beverage cans, glass bottles, aluminum bottles |

| Line speed | Fill level inspection (X-ray imaging width of 200 mm)

|

| Recording/control functions | Data distribution table for all products and defective product record. Results can be fed back to the filler valve and capper head controls. |

| Power source | AC 200V (3 phase) 20A |

| Equipment size (WxDxH) | 1000 x 1250 x 2300 mm (Height depends on the conveyor line height) |